Vibration tests

We test the mechanical resistance of items, equipment, and devices against the effects of vibration and impact. Vibration tests can be combined with climatic tests.

- Electrodynamic vibration and impact equipment, including a sliding desk.

- Multiaxial hydraulic systems.

- Lifespan testing of highly stressed parts for rail, air, and road transportation.

- Our own predefined profiles simulate real operation on roads and rail.

- Laboratory strain measurements of uniaxial and multiaxial stress.

- Seismic resistance tests (items, devices, and equipment).

The test lab is equipped with two single-axial electrodynamic vibration and shock desks, which can be combined with a climatic chamber.

The test lab is also equipped with a hydraulic system for multiaxial stress in vibration tests with a total mass up to 10 tonnes. The hydraulic system permits, for example, a road profile to be replicated and degrees of vibration generated freely.

Benefits:

- Combining the equipment allows mechanical and climatic tests to be conducted simultaneously (a climatic chamber can be positioned over a vibration desk as necessary).

- The ability to tune into any specified signal in the range defined above at any specified place on the equipment.

- FEM analyses combined with verification.

- Predefined road and rail profiles for vibration testing, with the option to significantly accelerate lifespan tests based on real acceleration.

- Vibration testing in accordance with ASTM (transporting applications).

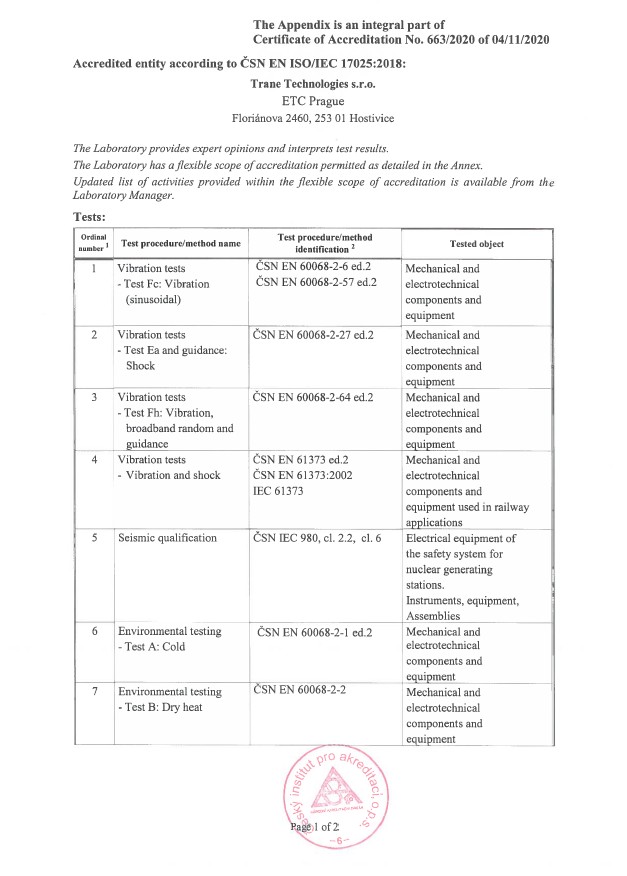

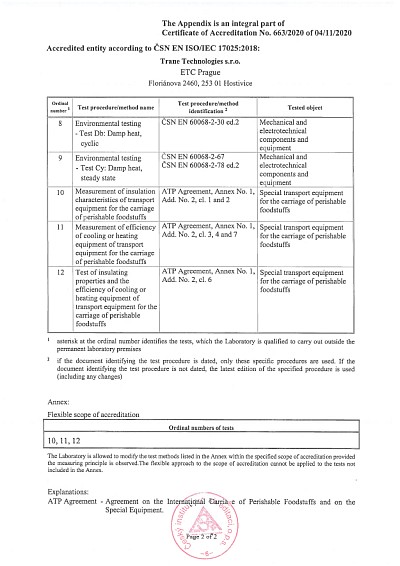

- Our accredited tests are conducted under the following standards:

| Vibration sinusoidal |

ČSN EN 600068-2-6 ČSN EN 600068-2-57 |

Environmental testing - Part 2: Tests Fc: Vibration (sinusoidal) Environmental testing - Part 2-57: Tests - Test Ff: Vibration - Time-history method |

|---|---|---|

| Shock test | ČSN EN 600068-2-27 | Basic environmental testing procedures. Part 2: Tests. Test Ea and quidance: Shock |

| Broad-band random vibration | ČSN EN 600068-2-64 | Environmental testing. Part 2: Test methods. Test Fh: Vibration, broad-band random |

| Railway applications | ČSN EN 61373 | Railway applications - Rolling stock equipment - Shock and vibration tests |

| Seismic qualification | ČSN IEC 980 | Recommended practices for seismic qualification of electrical equipment of the safety system for nuclear generating stations |

Specification of single-axial electrodynamic vibration and shock equipment: TIRA TV59349

- peak force at sinusoidal vibration: 49 kN,

- RMS force at random vibration: 48 kN,

- peak force at half-sinusoidal shock: 148 kN,

- max. deviation amplitude 50 mm

- max. speed sinusoidal/shock 2/2,5 m/s

- max.acceleration: 100/224 G,

- maximum sample weight: 900 kg,

- frequency range: 5 Hz to 2000 Hz,

- vibration test can be combined with a climatic chamber:

- chamber size 1,5 m x 1,5 m x 1,1 m (volume 2.5 m3),

- temperature range: -40 ° to +180 °C,

- temperature gradient: 10 °C /min,

- humidity range: 5 % to 95 %,

Specification of single-axial electrodynamic vibration and shock equipment: TIRA S 59356/AIT–480

- peak force at sinusoidal vibration: 56 kN,

- RMS force at random vibration: 56 kN,

- peak force at half-sinusoidal shock: 160 kN,

- max. deviation amplitude sinusoidal/random/shock 63.5/63.5/76.2 mm

- max. speed sinusoidal/random/shock 2/2/3.5 m/s

- max.acceleration: 100/80/350 G,

- maximum sample weight: 910 kg,

- frequency range: 5 Hz to 2500 Hz,

- vibration test can be combined with a climatic chamber:

- chamber size 1,5 m x 1,5 m x 1,1 m (volume 2.5 m3),

- temperature range: -40 ° to +180 °C,

- temperature gradient: 10 °C /min,

- humidity range: 5 % to 95 %,

Specification of Multi-Axial vibration and shock equipment:

- Electro-hydraulic loading system with 24 independent control channels with acquisition system for acceleration and displacement,

- multi-axial stress (3 axis on same time) in all 6 degrees of freedom (16 independent measurement channels, 8 independent control channels),

- fixation base: 12 m x 8 m with a universal modular fixation system,

- currently 3 states - with a maximum sample weight 10 000 kg (frame size 3.5 m x 2.5 m),

- maximum peak force in horizontal direction: 126 kN, in second direction 63 kN,

- maximum peak force in vertical direction: 252 kN,

- frequency range: 2 Hz to 200 Hz.

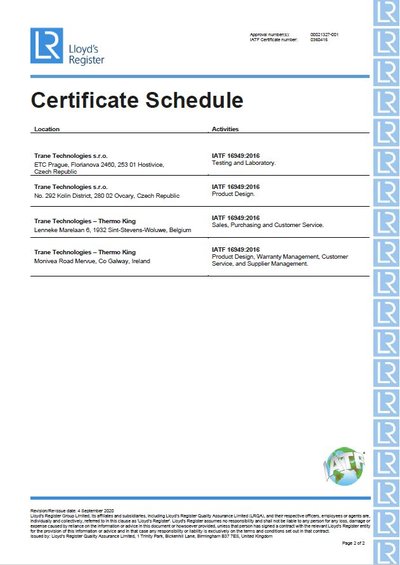

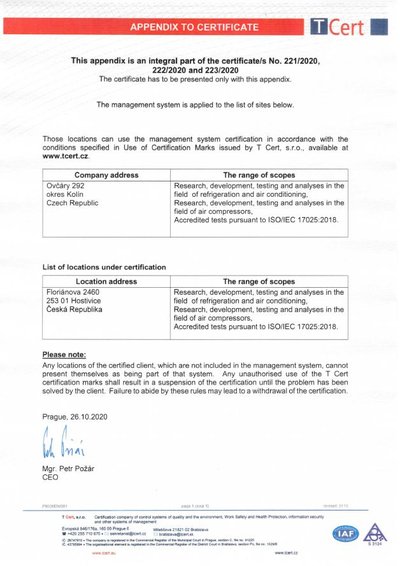

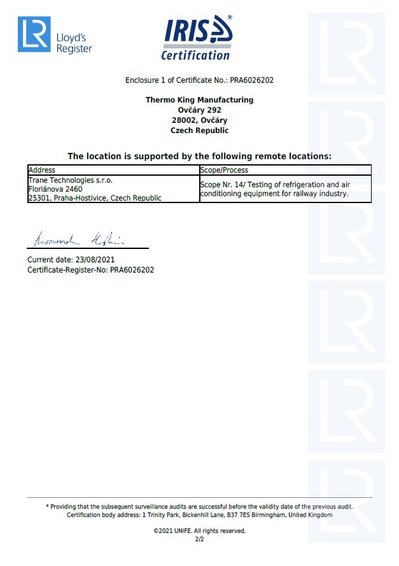

The European Test Centre focuses on quality, environment, and safety, and is certified in accordance with the following standards:

EN ISO/IEC 17025 (General requirements for the competence of testing and calibration laboratories)

IATF 16949 (Quality Management System)

ISO 14001 (Environmental Management System)

ISO 45001 (Occupation Health and Safety Management System)

ISO 5001 (Energy Management System)

IRIS (The International Railway Industry Standard)

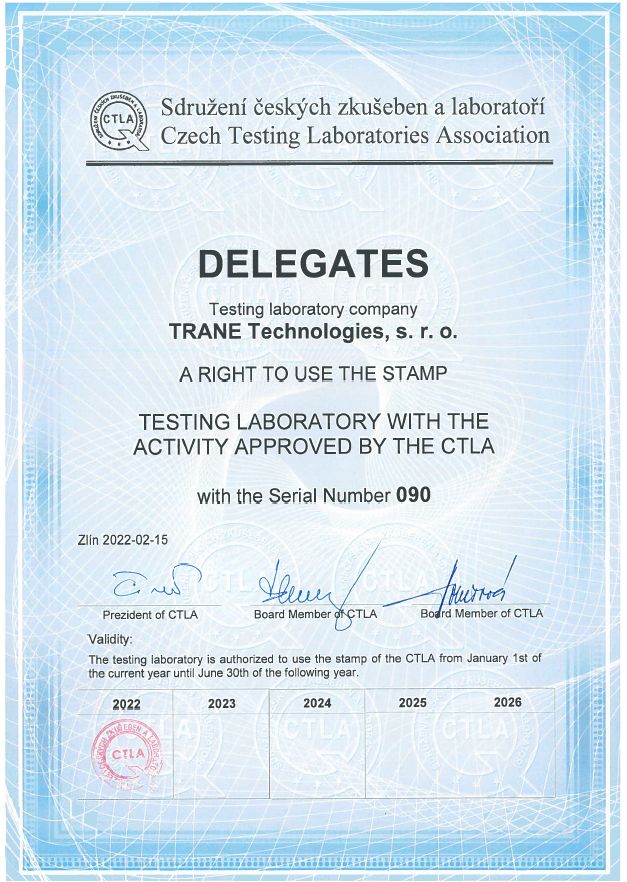

CTLA (Czech Testing Laboratories Association)

EUROLAB (European Federation of National Associations of Measurement, Testing and Analytical Laboratories)

ATP certification (The Agreement on the International Carriage of Perishable Foodstuffs)

ETC Prague is authorized by the Ministry of Transport of the Czech Republic to carry out the activities of the ATP and is included in the official UN list. For more detailed information about ATP tests, please visit the following web page: www.frcatp.cz/en/.

Do you need assistance with testing?

Write to us and we will contact you soon with possible solutions.