Components testing

We test compressors designed for refrigeration and air conditioning units, fans, and electric machines.

- Performance and life tests of compressors

- Measurement with all standard refrigerants, including CO2 and A2L and A3 refrigerants

- Electric machine tests

REFRIGERATION COMPRESSOR TESTING

Compressor types: Electric compressors (scroll, rotary, piston) and variable speed compressors with drive

The test lab has four measuring devices available for testing the performance of compressors, both for conventional refrigerants, alternative refrigerants, including subcritical and transcritical CO2, and A2L und A3 refrigerants with a maximum output of 45 kW.

The test lab also has 14 chambers for stress and lifespan testing of compressors at temperatures from -35 ° C to +45 ° C.

ELECTRIC MACHINE TESTS

We offer dynamometer measurements for motors and generators with a rated power of up to 25 kW.

- Asynchronous and synchronous machines

- Insulation resistance measurement

- Winding resistance measurement

- Load characteristics

- Warming test

- Empty measurement

- Moment characteristic

- Short measurement

- Calculation of losses from empty measurement

- Calculation of efficiency from load characteristics

- Lifetime tests, sequence up to 20 points

REFRIGERATION COMPRESSORS TEST LABS

- CMP – Refrigeration Compressor Performance Test Labs

- Traditional refrigerant (R134a, R407C, R410A, R452A)

- Open shaft (500-6000 r.p.m.) or hermetic compressors

- Performance ranges: 0,6 kW to 45 kW

- Alternative and A2L and A3 refrigerant (R744, R1234yf, HFO1234yf, R290, R1270)

- Performance ranges: 2kW to 45 kW

- Pressure range: 40 bar to 130 bar

- Traditional refrigerant (R134a, R407C, R410A, R452A)

- Stability of the environment: according to EN 13771-1

- CMP – Refrigeration Compressor Endurance Test Labs

- Traditional and A2L and A3 refrigerant (R134a, R407C, R410A, R452A, R290, R1270)

- Performance ranges: 0,6 kW to 45 kW

- Stability of the environment: according to compressors producers and internal company standards

ELECTRIC MACHINE TESTS

We offer dynamometer measurements for engines and generators with a rated power of up to 25 kW.

- Harmonic voltage supply for 230 V (105 A), 400 V (55 A) and 690 V (35 A), 50 Hz and 60 Hz engines, rated output 25 kW

- PWM output 3x 0-400 V, 73 A, 0 Hz-550 Hz

- Secondary converter for small machines, power 4 kW, rated current 9.2 A

Technical parameters of the asynchronous dynamometer:

- rated power 28 kW

- nominal moment 198 Nm

- rated speed 1350 min-1

- direct torque measurement using the strain gauge shaft Kistler 4541A

- adjustable table - shaft axis height 102-202 mm, test engine area 500x500 mm, up to 100 kg

- measurement accuracy - torque 0.02 %, i.e. +/- 0.06 Nm; speed 0.00 5%, el.current 0.01 %

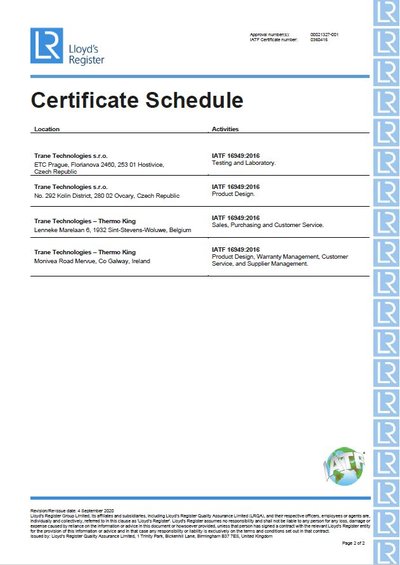

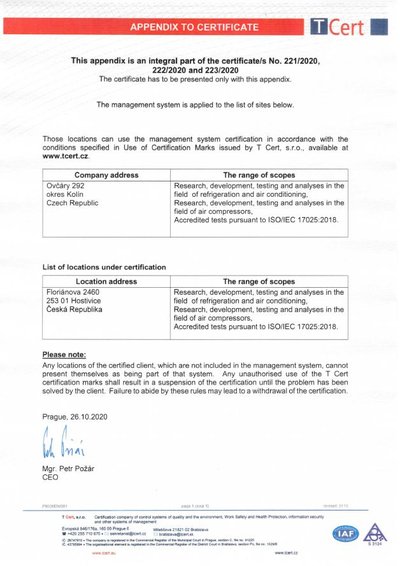

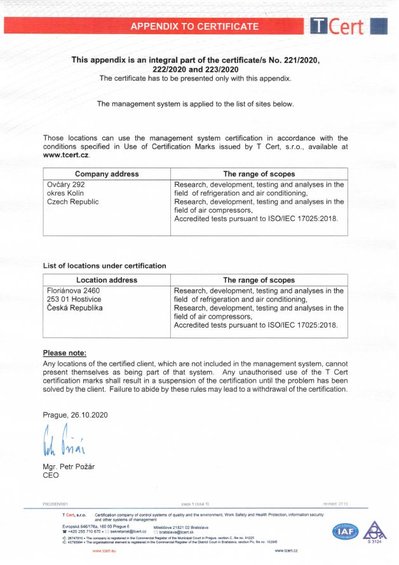

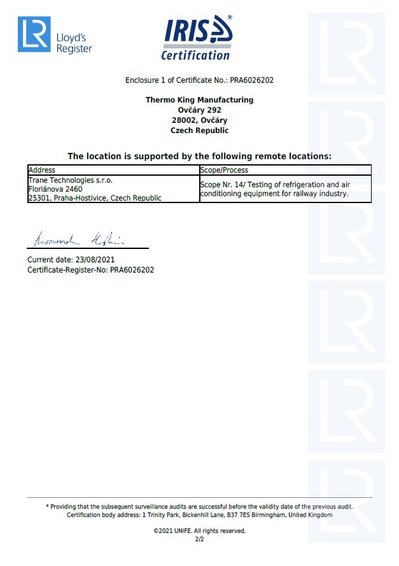

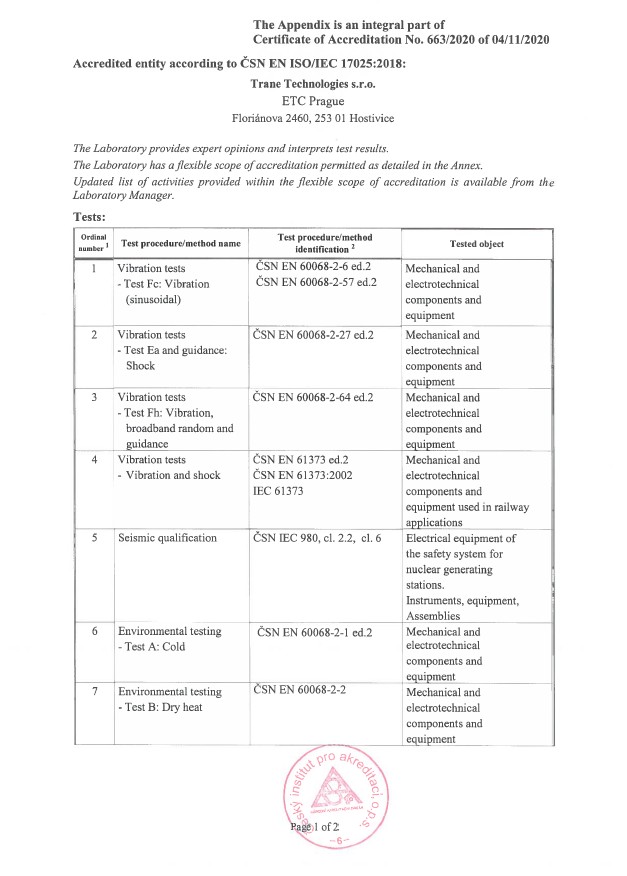

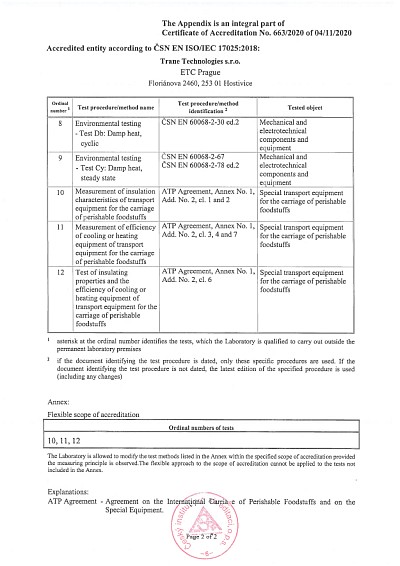

The European Test Centre focuses on quality, environment, and safety, and is certified in accordance with the following standards:

EN ISO/IEC 17025 (General requirements for the competence of testing and calibration laboratories)

IATF 16949 (Quality Management System)

ISO 14001 (Environmental Management System)

ISO 45001 (Occupation Health and Safety Management System)

ISO 5001 (Energy Management System)

IRIS (The International Railway Industry Standard)

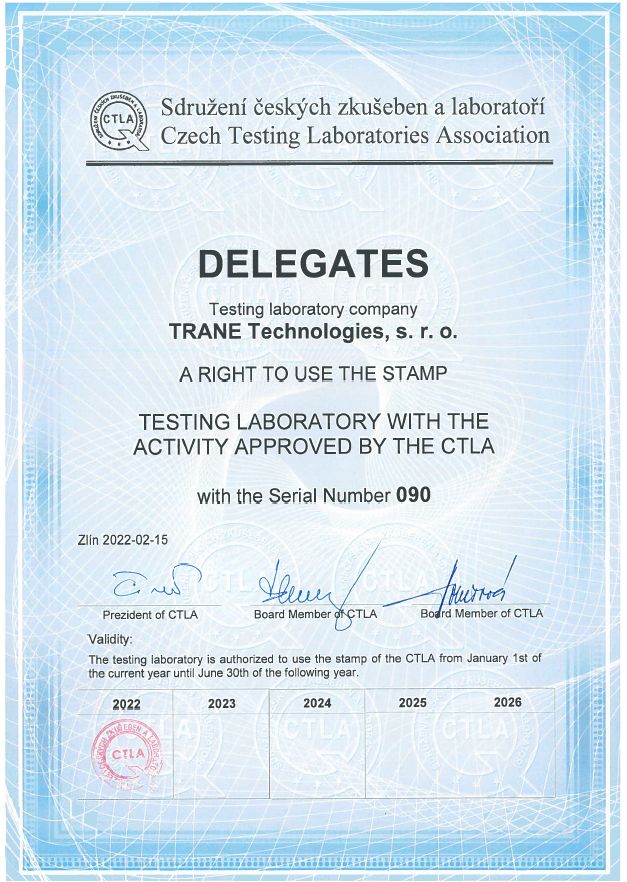

CTLA (Czech Testing Laboratories Association)

EUROLAB (European Federation of National Associations of Measurement, Testing and Analytical Laboratories)

ATP certification (The Agreement on the International Carriage of Perishable Foodstuffs)

ETC Prague is authorized by the Ministry of Transport of the Czech Republic to carry out the activities of the ATP and is included in the official UN list. For more detailed information about ATP tests, please visit the following web page: www.frcatp.cz/en/.

Do you need assistance with testing?

Write to us and we will contact you soon with possible solutions.